HDPE-PP-PET-ABS-PS-HIPS-PVC Sheet Extrusion Line

- item No : PCX-1200

- Model NO.SJSZ120x33Customized

- Inquiry now

Detailed

INTRODUCTION

Plastic sheets range: 300-8000mm

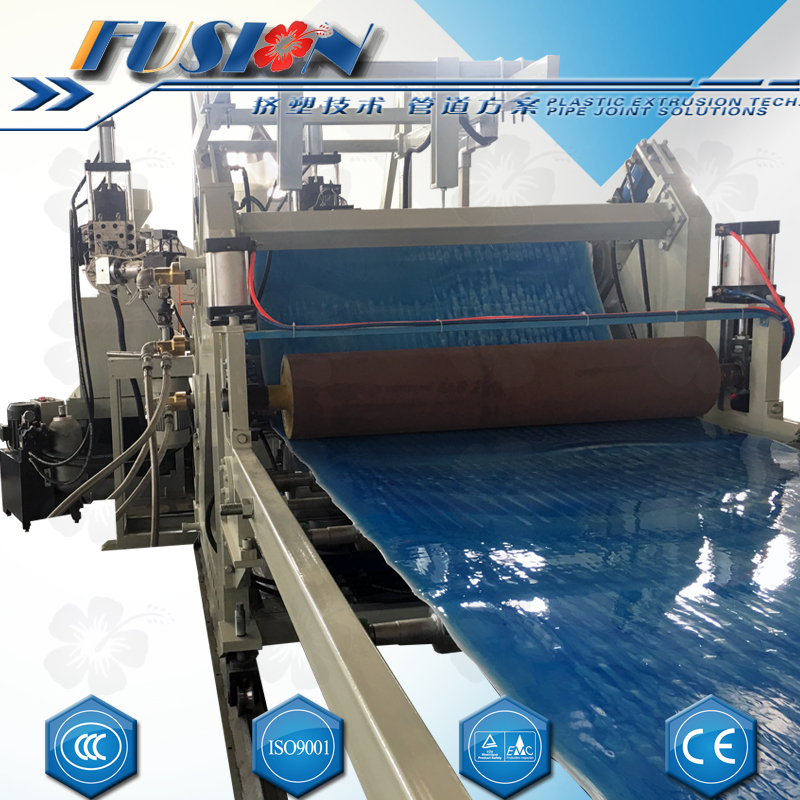

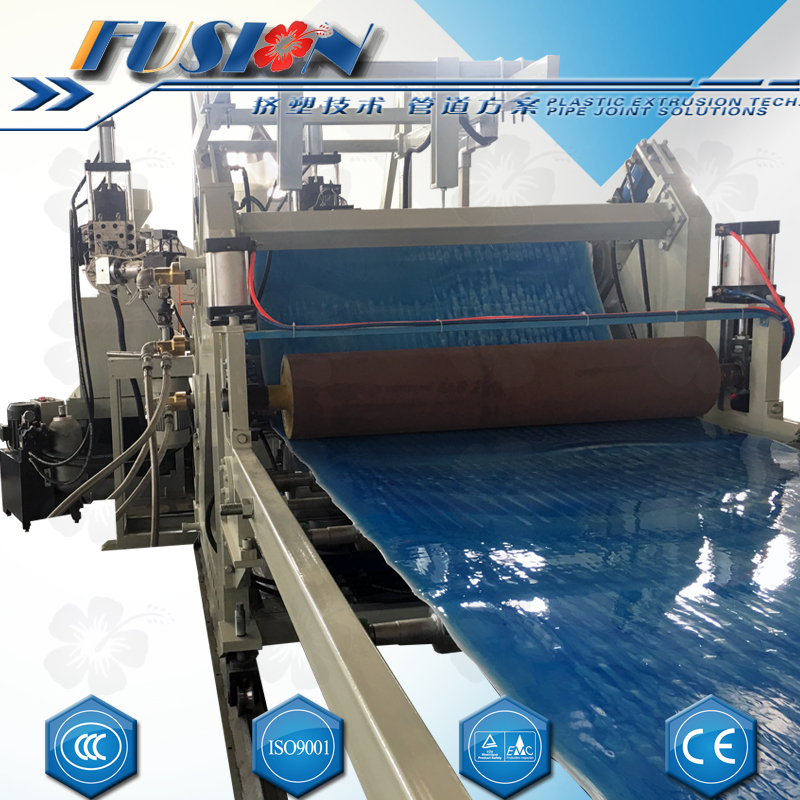

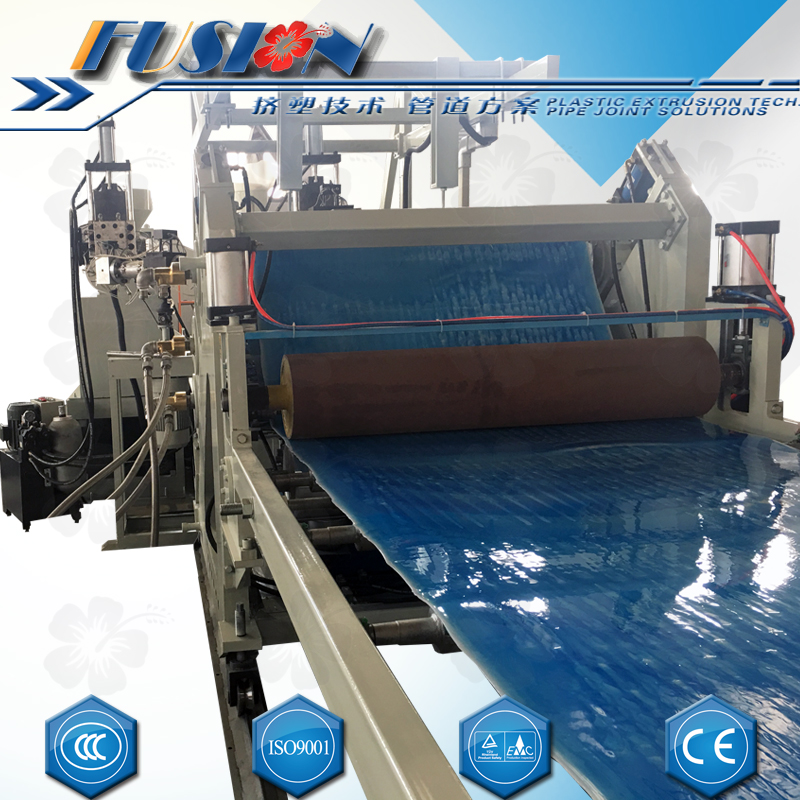

Plastic sheets are extrued with mold and surface is treated with hot-stamping machine (3 rollers Calender) directly in line, which makes a smooth surface.

Composition of Equipments

1set Vacuum loader

1set Hopper Dryer.

1set Efficient single screw extruder or twin screw extruder (Long L/D ratio)

1set T-Die Mould

1set 3-Roller Calender

1set Cooling frame

1set Hauling machine

1set Cutting machine

1set Stacker

Machine List:

1.Extruder: Include Single Screw Extruder & Coincal Twin Screw Extruder:

adopting specially screw designs according to different materials make the high polymer micro-foam uniform plasticization, high extrusion. Imported famous brands AC inverter makes the rotation speed stable to ensure the main extruder and accessory machines move synchronously

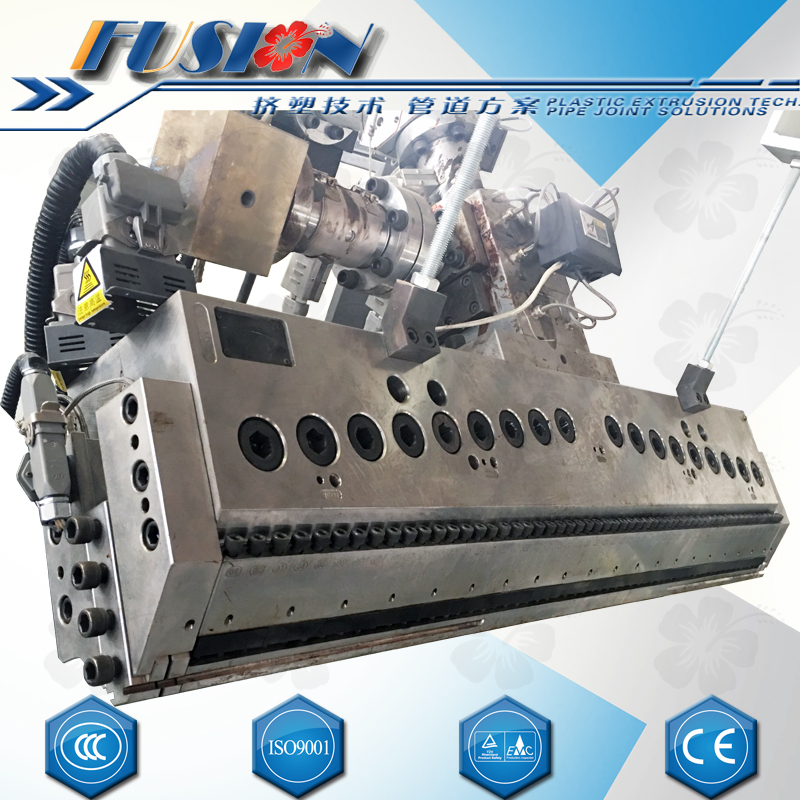

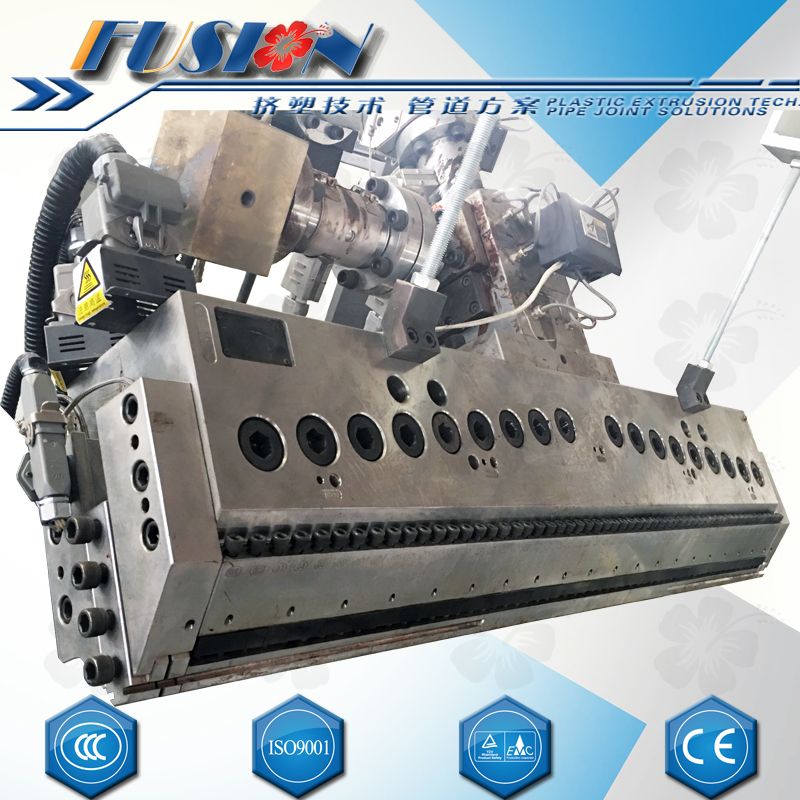

2. Die moulds:

material 40Cr, 45#, 3Cr17, it includes the die head parts, vacuum calibrator parts, water cooling tank parts

3.3-Roller Calender

adopts powerful oil/water heating system, easy to achieve satisfactory sheets quality. According to different moulds and different customer requirements, the roller can be optional as EMB style which could bring the manufacture with vaious of surface drawing.

4. Cooling frame

5. Haul off machine:

adopts special lifting technology, and has the features of stable running, reliable working, powerful hauling etc,

6. Cutting machine:

the moving speed of the cutting unit is synchronized with hauling speed. Through prseting,the cutting unit is capable for automatic cutting with fixed length. Dust recycling device is also equipped.

7.Other accessory machines:

high speed hot and cold mixer, plastic crusher, plastic pulverizer

Remak: Above table only for reference, for more detail infos, please check with us.

Type

PCX-150

PCX-170

PCX-180

PCX-80

Raw Material

PP,PE,ABS,PC

PP,PE,ABS,PC

PP,PE,ABS,PC

PVC

Width

1220-1500mm

1200-1500mm

1500-2000mm

1220mm

Thickness

3-30mm

3-30mm

3-30mm

3-30

Extruder Type

SJ150x35

SJ170x35

SJ180x35

SJSZ80x156

Outout

500kg/h

700Kg/h

800kg

450kg/h

- About Us

- Company Introduction

- Contact Us

[email protected]

[email protected] gongsong2010

gongsong2010 +86 18661986585

+86 18661986585